-

我也要用铁茶壶,普通茶民如何选心怡铁壶

一、为什么要用铁壶泡茶,与瓷壶,不锈钢壶有什么不同

铁壶烧水沸点温度更高,比一般不锈钢随手泡等要高出2-3度,且铁壶保温时间也更长,利用高温水泡茶,可激发和提升茶的香气。尤其对于普洱老茶而言,因陈化时间较长,是必须采用足够的高温水,才能淋漓尽致把其内质陈香和茶韵发挥出来,铁壶与普洱老茶实为绝配。

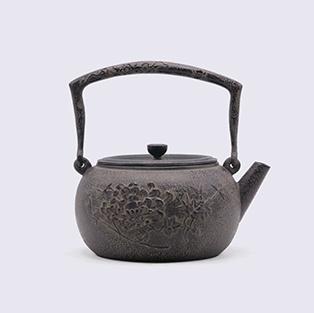

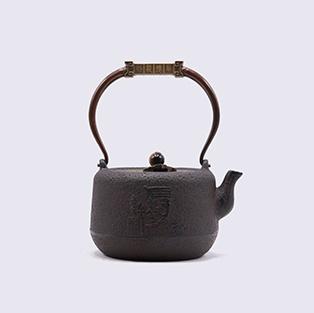

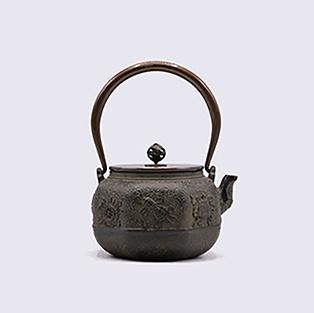

铁壶

我也要用铁茶壶,普通茶民如何选心怡铁壶

一、为什么要用铁壶泡茶,与瓷壶,不锈钢壶有什么不同

铁壶烧水沸点温度更高,比一般不锈钢随手泡等要高出2-3度,且铁壶保温时间也更长,利用高温水泡茶,可激发和提升茶的香气。尤其对于普洱老茶而言,因陈化时间较长,是必须采用足够的高温水,才能淋漓尽致把其内质陈香和茶韵发挥出来,铁壶与普洱老茶实为绝配。

铁壶

-

究竟什么样的铁壶才是好的铁壶

拥有一把日本老铁壶逐渐成为茶友们的追求。然而纵观市场上的真假铁壶,到底该怎样炼就火眼金睛,为自己挑一把称心如意的铁壶呢?接下来小编带大家炼就“火眼金睛”。

1、品相

一把老铁壶从卖家手中到你手,然后可以正常的使用,它是一个“生长”过程,是从“老”到“年轻”,是一个逆生长的过程。若卖家处理干

究竟什么样的铁壶才是好的铁壶

拥有一把日本老铁壶逐渐成为茶友们的追求。然而纵观市场上的真假铁壶,到底该怎样炼就火眼金睛,为自己挑一把称心如意的铁壶呢?接下来小编带大家炼就“火眼金睛”。

1、品相

一把老铁壶从卖家手中到你手,然后可以正常的使用,它是一个“生长”过程,是从“老”到“年轻”,是一个逆生长的过程。若卖家处理干

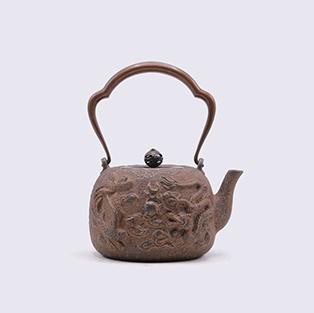

满载而归

满载而归 莲年如意

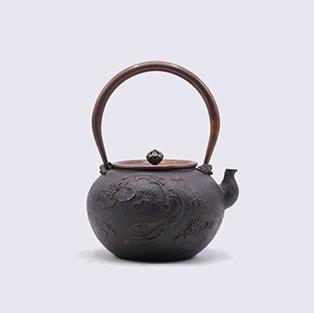

莲年如意 富贵吉祥

富贵吉祥 丰荣佛珠

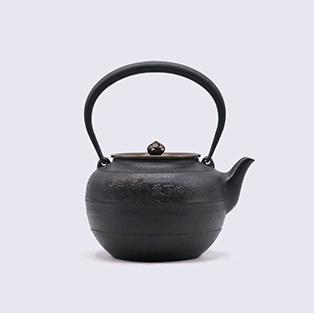

丰荣佛珠 多子多福

多子多福 蝶恋花

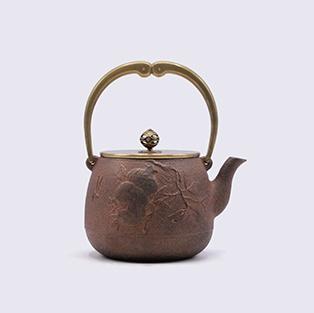

蝶恋花 标形厚德载物

标形厚德载物 八角神器

八角神器